RinasWeld

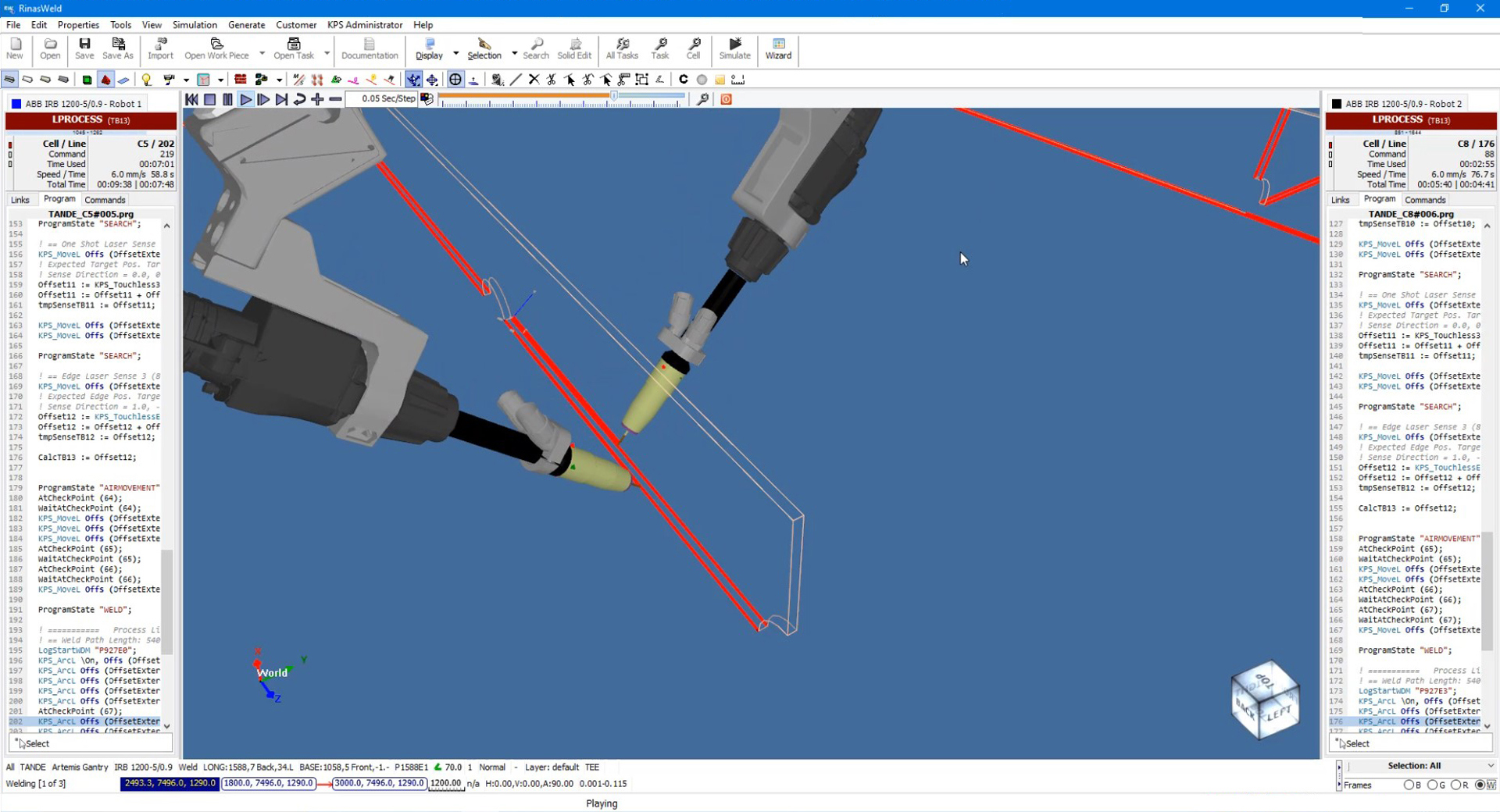

RinasWeld is KRANENDONK’s powerful software solution for automated welding operations. Instead of programming every robot movement manually, RinasWeld transforms your 3D design into a fully operational welding plan—quickly, reliably, and without errors.

Expertise in non-repetitive production

Modular solutions that scale with you

From CAD to weld in minutes

Smart by design

RinasWeld handles the complexity behind robotic welding — automatically detecting welds, selecting the right parameters, and generating safe robot paths. No programming, no trial-and-error. Just smart features working together to get your job done faster.

✅ Automatic weld recognition

RinasWeld scans your 3D model and instantly detects all weld seams — even on curved panels and complex structures. No manual selection. Just import and go.

✅ Smart parameter selection

Based on geometry and material, the right welding parameters are selected automatically. RinasWeld follows your WPS rules without human input.

✅ Collision-free motion

Robot paths are generated fully automatically and optimized for smooth, safe, and collision-free movement — even in tight spaces or complex assemblies.

✅ No programming needed

Forget coding. With RinasWeld, everything is driven by intelligent rules and CAD geometry — from detection to execution.

✅ Production-ready in minutes

No lengthy setup. No complex programming. RinasWeld is designed for speed and ease of use. With just a few guided steps, your weld plan is ready. All in a matter of minutes. Even for one-offs or constantly changing designs.

From 3D model to automated welding

-

Import 3D CAD Model

Easily import your 3D model into RinasWeld. The software supports formats like .STEP, .IGES, .IFC, and .ATX.

-

Automatic weld detection

RinasWeld automatically analyzes the geometry and identifies weld locations and types. The correct weld parameters (WPS) are selected from your library.

-

Intelligent path planning

The system generates collision-free, robot-optimized weld paths — even in tight or complex geometries.

-

Optional simulation

Run a full simulation to verify the weld sequence, torch positions, and motion logic before going live.

-

One-click production

On the shop floor, the operator loads the program and starts the welding process instantly — no manual programming needed.

How RinasWeld stands out

Unlike traditional systems, RinasWeld removes complexity and manual steps. From flexible compatibility to true no-code automation, see how it compares to other solutions on the market.

Features

RinasWeld by KRANENDONK

Other systems

Fully automatic weld path generation from 3D CAD

✅

⚪ (semi-automatic)

No robot programming or CAM needed

✅

⚪ (often required)

Designed for high-mix, one-off production

✅

⚪ (some support it)

Works with standard CAD formats (.STEP, .ATX, .IFC)

✅

✅

Vendor-independent: works with all major robot and welding brands

✅

⚪ (often brand-locked)

Auto WPS selection and weld strategy from model

✅

⚪ (manual setup often needed)

Scales from single robot to full production line

✅

✅

Optional simulation before execution

✅

✅

Adaptive real-time welding (e.g. scanning, seam tracking)

❌ (optional)

✅ (in higher-end systems)

Insights from our customers

Our customers face tough production targets, tight deadlines, and increasing demands on quality. With KRANENDONK’s automation solutions, they’ve turned those challenges into efficiency, control, and growth. These stories show how leading manufacturers accelerate output, improve consistency, and reduce costs — by automating with KRANENDONK.

Berry Metall increases efficiency and flexibility with KRANENDONK robotic welding station

Welkom bij WordPress. Dit is je eerste bericht. Bewerk of verwijder het, start dan met schrijven! Lorem ipsum dolor sit...

Lamprell expands offshore wind capabilities with KRANENDONK welding automation

Welkom bij WordPress. Dit is je eerste bericht. Bewerk of verwijder het, start dan met schrijven! Lorem ipsum dolor sit...

Damen Galati embraces modern technologies in micro-panel welding

Welkom bij WordPress. Dit is je eerste bericht. Bewerk of verwijder het, start dan met schrijven! Lorem ipsum dolor sit...