Automation Consulting

Automation starts long before the first robot is installed. At KRANENDONK, we help you define what’s worth automating, how to optimize your production flow, and what systems will truly deliver value.

Our consulting services connect strategy with execution—so you don’t just automate, you improve.

Expertise in non-repetitive production

Modular solutions that scale with you

From CAD to weld in minutes

From insight to implementation

Our consulting approach is practical, data-driven, and focused on real production outcomes. Whether you’re taking your first steps in automation or scaling up an existing system, we support you with the insight and structure needed to move forward with confidence.

Understand Your production reality

Every factory is unique. We start by listening, observing, and analyzing your current flow—so we truly understand your challenges and opportunities before talking solutions.

Shape a smart automation vision

Together, we define where automation adds real value. You get clear goals, technical feasibility, and a practical strategy—based on logic, not guesswork.

Design what works in practice

We translate strategy into action: with tailored layouts, integration plans, and system logic that fits your products, people, and production mix.

Back it up with a business case

We deliver the numbers you need to move forward—ROI, investment scope, and a realistic roadmap. Ready to build, or ready to convince stakeholders.

Why our consulting works in practice—not just on paper

True automation doesn’t start with a product. It starts with understanding the flow, the people, and the limits of your production. That’s our starting point.

We don’t believe in off-the-shelf blueprints. Every consultation is grounded in:

- A deep understanding of your current factory dynamics

- Technical insight into what robotic systems can realistically handle

- And a practical mindset focused on buildable, scalable, and maintainable automation

The result? Advice that respects your reality. And a roadmap you can execute.

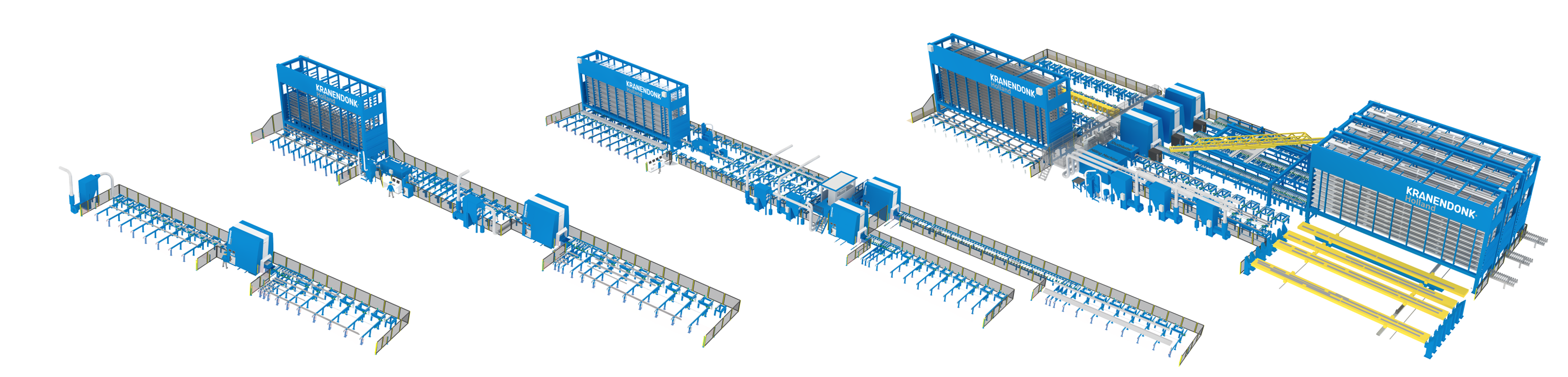

From standalone to full production line

Whether you’re automating a single station or building an entire production line, KRANENDONK offers scalable solutions that grow with your business.

Our systems are modular, future-ready, and tailored to your specific needs—no matter the size or complexity of your operation.

Not sure where to start? Our consulting team helps you define the right scope, so your automation delivers value from day one—and keeps delivering as you scale.

Not sure where to start?

We get that. That’s why we’ve answered the key questions companies ask when exploring automation with KRANENDONK—for when you need clarity before taking the first step.

Just send us your layout, production specs, or a short description of your challenge to

sales@kranendonk.com. We’ll take a look and get back to you with tailored advice—no strings attached.

Not at all. We work with companies of all sizes—from those taking their first step in automation to those scaling up entire lines. Our approach adapts to your ambition, not just your company size.

Ideally, as early as possible—before layout or investment decisions are made. We help you avoid costly redesigns by setting the right course from the start. Even if you’re just exploring options, we’re happy to think along.

Yes—our consulting can clarify whether automation adds value today or in the near future.

From robotic feasibility to layout flow or welding logic—we help untangle complex automation challenges. If it affects production speed, accuracy, or scalability, we’re the right partner to assess it.

Absolutely. We support you with technical input, budget forecasting, and ROI scenarios to strengthen your business case. You’ll enter discussions with confidence and clarity.

Insights from our customers

Our customers face tough production targets, tight deadlines, and increasing demands on quality. With KRANENDONK’s automation solutions, they’ve turned those challenges into efficiency, control, and growth. These stories show how leading manufacturers accelerate output, improve consistency, and reduce costs — by automating with KRANENDONK.

Berry Metall increases efficiency and flexibility with KRANENDONK robotic welding station

Welkom bij WordPress. Dit is je eerste bericht. Bewerk of verwijder het, start dan met schrijven! Lorem ipsum dolor sit...

Lamprell expands offshore wind capabilities with KRANENDONK welding automation

Welkom bij WordPress. Dit is je eerste bericht. Bewerk of verwijder het, start dan met schrijven! Lorem ipsum dolor sit...

Damen Galati embraces modern technologies in micro-panel welding

Welkom bij WordPress. Dit is je eerste bericht. Bewerk of verwijder het, start dan met schrijven! Lorem ipsum dolor sit...