About us

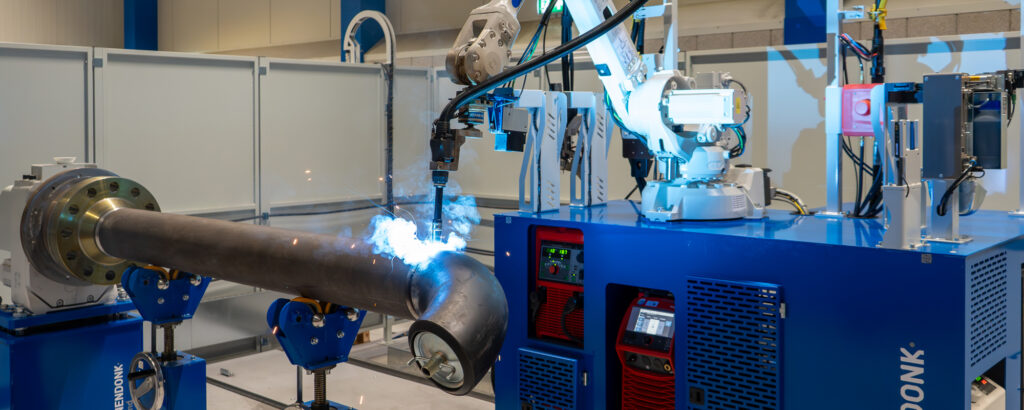

Traditionally, robots are used for repetitive tasks. At KRANENDONK, we make the opposite possible. Our robot lines are designed for non-repetitive production, tailored to industries where products are never the same. This opens a world of automation opportunities for manufacturers.

Expertise in non-repetitive production

Modular solutions that scale with you

From CAD to weld in minutes

From humble beginnings to global leadership

KRANENDONK was founded in 1983 with a clear mission: to bring true intelligence to industrial robotics. At a time when robots could only repeat predefined motions, we recognized a crucial gap—what these machines needed wasn’t just mechanical precision, but real control, adaptability, and logic.

By developing our own smart sensors and control software, we transformed static automation into flexible production power. This innovation quickly positioned us as a trusted partner for industries looking to automate complex, non-repetitive tasks.

At the core of modern manufacturing

Over the years, our technology evolved from standalone robotic solutions into fully integrated systems that orchestrate entire production lines—seamlessly connecting engineering, cutting, logistics, welding, and data. Today, KRANENDONK systems operate at the core of advanced manufacturing sites across the globe.

And while we’ve grown into a leader in robotic automation, our mindset remains the same: stay curious, stay hands-on, and keep solving real problems with smart technology that fits.

Industries we serve

Shipbuilding

Large panels, heavy sections, and tight delivery schedules—shipyards demand efficiency without sacrificing quality. Our automated welding and cutting solutions speed up production, reduce manual labor, and deliver consistent results for every vessel.

Floating Wind

As floating wind farms scale up, so does the complexity of their components. We support this growing sector with advanced robotic welding lines that handle size, weight, and variability—helping manufacturers scale up while keeping control.

Offshore Oil & Gas

In offshore fabrication, every weld counts. KRANENDONK’s robotic systems are built to deliver precision and repeatability under the toughest conditions. Our software ensures collision-free movements, even on large and complex structures.

Structural Steel

Speed and flexibility are key in structural steel. Our solutions automate processes like part identification, fit-up, and welding—reducing lead times and allowing fabricators to handle custom projects with industrial efficiency.

More than just a supplier

KRANENDONK is more than just a supplier of robotic systems. As a Robot Technology Centre, we take a broader role—one that combines engineering, integration, support, and long-term partnership. It’s a role that allows us to guide our customers from first idea to successful daily operation.

We design and deliver high-end robotic equipment, but our involvement goes much deeper. Every solution we offer is developed in-house, both hardware and software, ensuring full control over quality, integration, and innovation. This engineering power allows us to create flexible systems that adapt to our customers’ processes—not the other way around.

The people behind your success

At KRANENDONK, it’s not just the technology that makes a difference—it’s the people behind it. Every robot, every line of code, every on-site visit is driven by a team that takes real ownership of your success.

We bring together specialists who combine deep technical knowledge with a hands-on, can-do mentality. Our culture is built on curiosity, responsibility, and long-term commitment—so you always know who you’re working with, and what they stand for.

Togetherness

We work as one team—with each other and with you. Open communication, shared goals, and real collaboration ensure your project runs smoothly, from start to finish.

Product innovation

We don’t settle for “good enough.” Our engineers challenge the status quo and develop smart, future-proof solutions that make your production faster, safer, and more flexible.

Quality & Customer Focus

We deliver systems that perform—day after day, year after year. You can count on us for reliable technology, honest advice, and fast support whenever it matters most.

Insights from our customers

Our customers face tough production targets, tight deadlines, and increasing demands on quality. With KRANENDONK’s automation solutions, they’ve turned those challenges into efficiency, control, and growth. These stories show how leading manufacturers accelerate output, improve consistency, and reduce costs — by automating with KRANENDONK.

Berry Metall increases efficiency and flexibility with KRANENDONK robotic welding station

Welkom bij WordPress. Dit is je eerste bericht. Bewerk of verwijder het, start dan met schrijven! Lorem ipsum dolor sit...

Lamprell expands offshore wind capabilities with KRANENDONK welding automation

Welkom bij WordPress. Dit is je eerste bericht. Bewerk of verwijder het, start dan met schrijven! Lorem ipsum dolor sit...

Damen Galati embraces modern technologies in micro-panel welding

Welkom bij WordPress. Dit is je eerste bericht. Bewerk of verwijder het, start dan met schrijven! Lorem ipsum dolor sit...